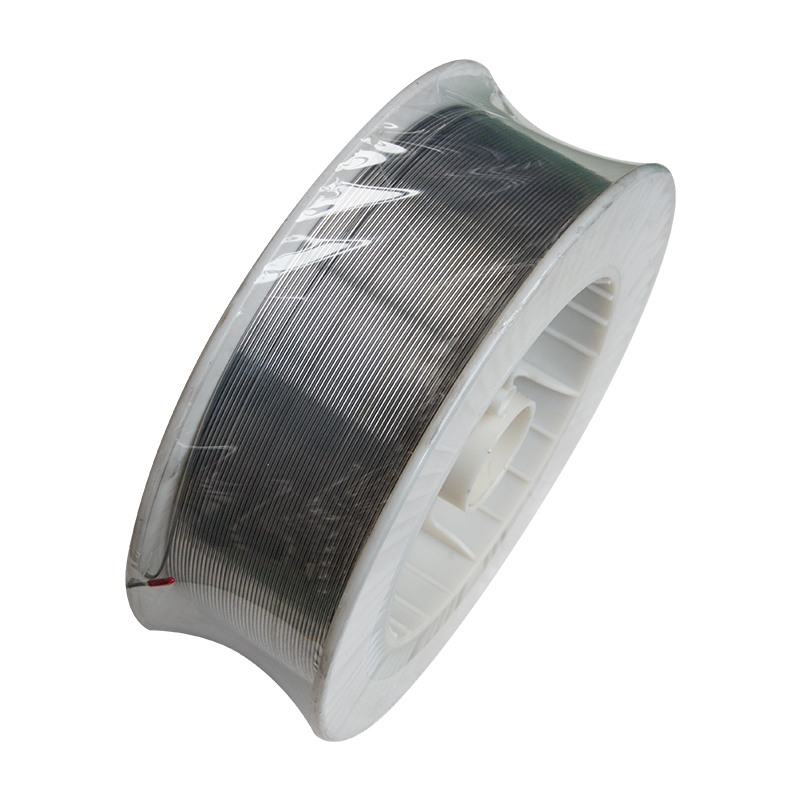

Vacon 12 Fe-Ni-Co Glass Sealing Alloy Wire Kovar Alloy Wire

Vacon 12Fe-Ni-Co glêsdichtingslegeringtriedKovarLegeringstried

(Algemiene namme:Kovar, Nilo K., KV-1, Dilver Po, Vacon 12)

Spesifikaasje:Blêd/Plaat, Bar/Rod/Tread/Spoel, Kapillêr/Piip/Buis

Grutteberik:

-*Fel_Dikte 0.1mm~40.0mm, breedte: ≤300mm, Tastân: kâld rôle (hjit), helder, helder gegloeid

-*RûnTrieddiameter 0.1mm ~ Diameter 5.0mm, Tastân: kâld lutsen, helder, helder gegloeid

—*Platte tried_Dia 0.5mm~Dia 5.0mm, lingte: ≤1000mm, tastân: flak rôle, helder gegloeid

—*Bar_Dia 5.0mm~Dia 8.0mm, lingte: ≤2000mm, tastân: kâld lutsen, helder, helder gegloeid

Dia 8.0mm ~ Dia 32.0mm, lingte: ≤2500mm, tastân: hjit rôle, helder, helder gegloeid

Dia 32.0mm ~ Dia 180.0mm, lingte: ≤1300mm, tastân: hjit smeiden, skille, draaid, hjit behannele

—*Kapillêr_OD 8.0mm~1.0mm, ID 0.1mm~8.0mm, lingte: ≤2500mm, Tastân: kâld lutsen, helder, helder gegloeid

-*Piip_OD 120mm~8.0mm, ID 8.0mm~129mm, lingte: ≤4000mm, Tastân: kâld lutsen, helder, helder gegloeid

Oanfraach:

Benammen brûkt yn elektryske fakuümkomponinten en emisjekontrôle, skokbuis, ûntstekkingsbuis, glêzen magnetron, transistors, sealplugs, relais, yntegreare circuits lead, chassis, beugels en oare húsfestingafdichtingen.

Normale gearstalling%

| Ni | 28,5~29,5 | Fe | Bal. | Co | 16.8~17.8 | Si | ≤0.3 |

| Mo | ≤0.2 | Cu | ≤0.2 | Cr | ≤0.2 | Mn | ≤0.5 |

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Treksterkte, MPa

| Koade fan betingst | Betingst | Tried | Strippe |

| R | Sêft | ≤585 | ≤570 |

| 1/4I | 1/4 hurd | 585~725 | 520~630 |

| 1/2I | 1/2 hurd | 655~795 | 590~700 |

| 3/4I | 3/4 hurd | 725~860 | 600~770 |

| I | Hurd | ≥850 | ≥700 |

Typyske fysike eigenskippen

| Dichtheid (g/cm3) | 8.2 |

| Elektryske wjerstân by 20ºC (Ωmm2/m) | 0.48 |

| Temperatuerfaktor fan resistiviteit (20ºC ~ 100ºC) X10-5/ºC | 3.7~3.9 |

| Curiepunt Tc/ºC | 430 |

| Elastyske modulus, E/Gpa | 138 |

Koëffisjint fan útwreiding

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20~60 | 7.8 | 20~500 | 6.2 |

| 20~100 | 6.4 | 20~550 | 7.1 |

| 20~200 | 5.9 | 20~600 | 7.8 |

| 20~300 | 5.3 | 20~700 | 9.2 |

| 20~400 | 5.1 | 20~800 | 10.2 |

| 20~450 | 5.3 | 20~900 | 11.4 |

Termyske geliedingsfermogen

| θ/ºC | 100 | 200 | 300 | 400 | 500 |

| λ/ W/(m*ºC) | 20.6 | 21.5 | 22.7 | 23.7 | 25.4 |

| It proses fan waarmtebehanneling | |

| Annealing foar stressferliening | Ferwaarme oant 470 ~ 540ºC en hâld 1 ~ 2 oeren. Kâld del |

| gloeien | Yn fakuüm ferwaarme oant 750 ~ 900ºC |

| Hâldtiid | 14 min ~ 1 oere. |

| Koelsnelheid | Net mear as 10 ºC/min ôfkuolle nei 200 ºC |

Produktkategoryen

-

Telefoan

-

E-post

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top