Wolkom op ús websiden!

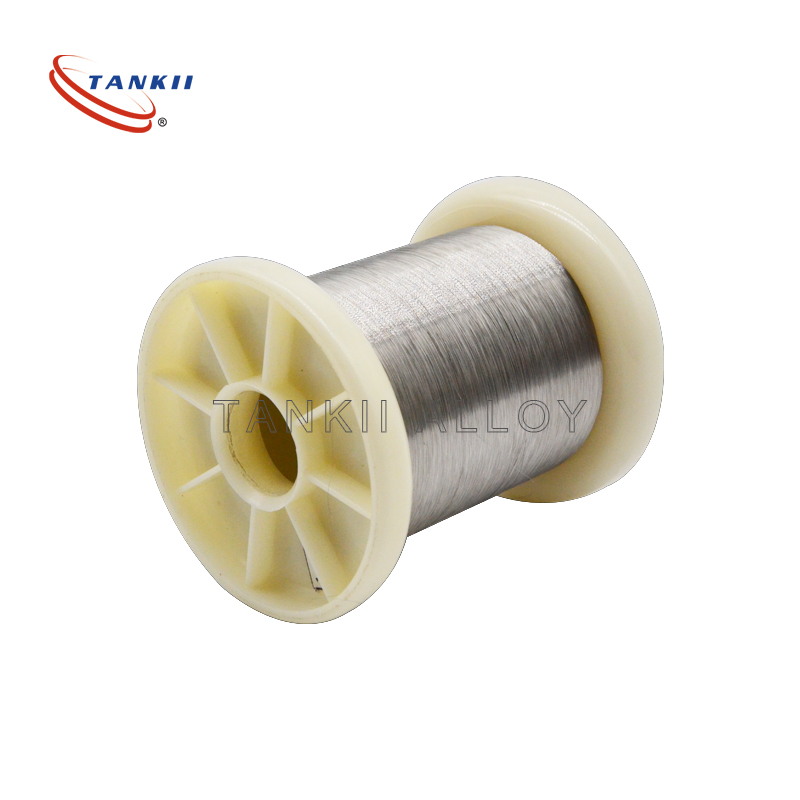

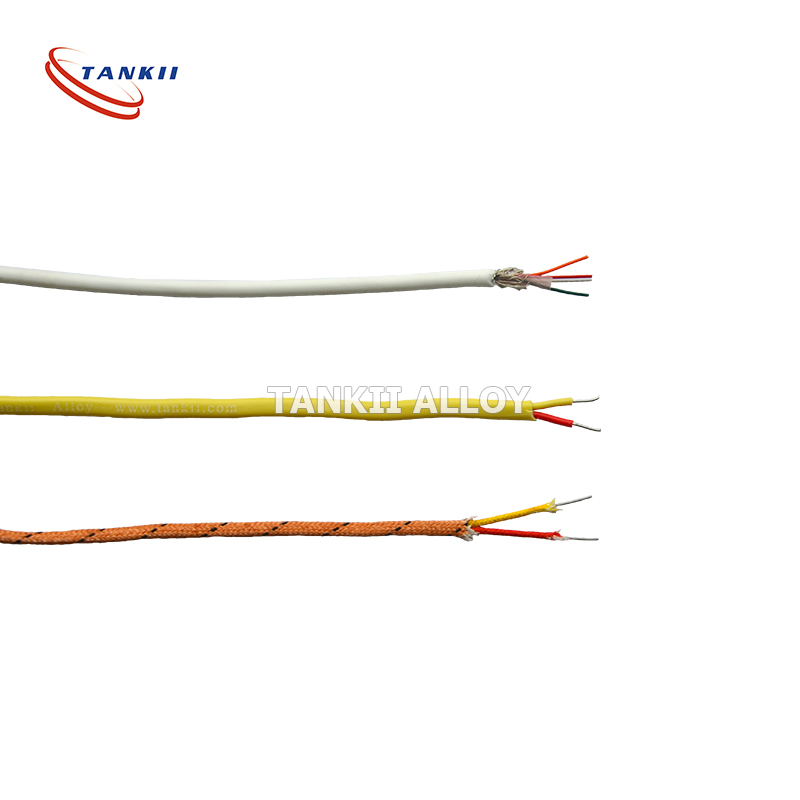

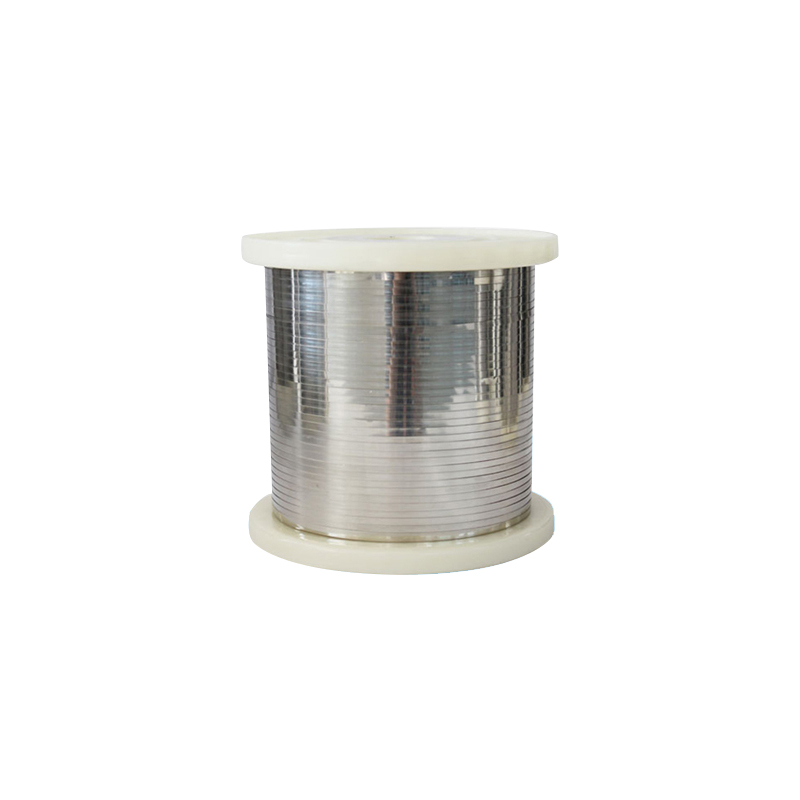

X20h80 Ferwaarmingsweerstandsdraad (Nicr80/20)

| Gemyske gearstalling en eigenskippen: | ||||

| Eigenskippen/Graad | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | |

| Haadgemyske gearstalling (%) | Ni | Bal. | Bal. | 55.0-61.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | |

| Maksimale wurktemperatuer (ºC) | 1200 | 1250 | 1150 | |

| Wjerstân by 20ºC (μ Ω · m) | 1.09 | 1.18 | 1.12 | |

| Dichtheid (g/cm3) | 8.4 | 8.1 | 8.2 | |

| Termyske geliedingsfermogen (KJ/m²· h² ºC) | 60.3 | 45.2 | 45.2 | |

| Koëffisjint fan termyske útwreiding (α × 10-6/ºC) | 18 | 17 | 17 | |

| Smeltpunt (ºC) | 1400 | 1380 | 1390 | |

| Ferlinging (%) | > 20 | > 20 | > 20 | |

| Mikrografyske struktuer | austenyt | austenyt | austenyt | |

| Magnetyske Eigenskip | net-magnetysk | net-magnetysk | net-magnetysk | |

| Eigenskippen/Graad | NiCr 35/20 | NiCr 30/20 | Karma | Evanohm | |

| Haadgemyske stof Gearstalling (%) | Ni | 34.0-37.0 | 30.0-34.0 | Bal | Bal |

| Cr | 18.0-21.0 | 18.0-21.0 | 19.0-21.5 | 19.0-21.5 | |

| Fe | Bal. | Bal. | 2.0-3.0 | - | |

| Maksimale wurktemperatuer (ºC) | 1100 | 1100 | 300 | 1400 | |

| Wjerstân by 20ºC (μ Ω · m) | 1.04 | 1.04 | 1.33 | 1.33 | |

| Dichtheid (g/cm3) | 7.9 | 7.9 | 8.1 | 8.1 | |

| Termyske geliedingsfermogen (KJ/m²· h²°C) | 43.8 | 43.8 | 46 | 46 | |

| Koëffisjint fan termyske Útwreiding (α × 10-6/ºC) | 19 | 19 | - | - | |

| Smeltpunt (ºC) | 1390 | 1390 | 1400 | 1400 | |

| Ferlinging (%) | > 20 | > 20 | 10-20 | 10-20 | |

| Mikrografyske struktuer | austenyt | austenyt | austenyt | austenyt | |

| Magnetyske Eigenskip | net-magnetysk | net-magnetysk | net-magnetysk | net-magnetysk | |

| Gemyske gearstalling | Nikkel 80%, Chroom 20% |

| Betingst | Helder/Soer wyt/Oksidearre kleur |

| Diameter | 0.018mm~1.6mm yn spoel, 1.5mm-8mm pakking yn spoel, 8~60mm yn roede |

| Nichrome rûne tried | Diameter 0.018mm ~ 10mm |

| Nichrome lint | Breedte 5~0.5mm, dikte 0.01-2mm |

| Nichrome Strip | Breedte 450mm ~ 1mm, dikte 0.001m ~ 7mm |

| Diameter | 1.5mm-8mm ynpakking yn spoel, 8~60mm yn roede |

| Klasse | Ni80Cr20, Ni70/30, Ni60Cr15, Ni60Cr23, Ni35Cr20Fe, Ni30Cr20 Ni80, Ni70, Ni60, Ni40, |

| Foardiel | De metallurgyske struktuer fan nichrome jout har in tige goede plastisiteit as se kâld binne. |

| skaaimerken | Stabile prestaasjes; Anti-oksidaasje; Korrosjebestriding; Hege temperatuerstabiliteit; Uitstekende spoelfoarmingsfermogen; Uniforme en moaie oerflakkondysje sûnder flekken. |

| Gebrûk | Ferwaarmingseleminten fan wjerstân; Materiaal yn metallurgy, Húshâldlike apparaten; Mechanyske produksje en oare yndustryen. |

| Wjerstânsdraden | ||

| RW30 | W.Nr 1.4864 | Nikkel 37%, Chroom 18%, Izer 45% |

| RW41 | UNS N07041 | Nikkel 50%, Chroom 19%, Kobalt 11%, Molybdeen 10%, Titanium 3% |

| RW45 | W.Nr 2.0842 | Nikkel 45%, Koper 55% |

| RW60 | W.Nr 2.4867 | Nikkel 60%, Chroom 16%, Izer 24% |

| RW60 | UNS NO6004 | Nikkel 60%, Chroom 16%, Izer 24% |

| RW80 | W.Nr 2.4869 | Nikkel 80%, Chroom 20% |

| RW80 | UNS NO6003 | Nikkel 80%, Chroom 20% |

| RW125 | W.Nr 1.4725 | Izer BAL, Chroom 19%, Aluminium 3% |

| RW145 | W.Nr 1.4767 | Izer BAL, Chroom 20%, Aluminium 5% |

| RW155 | Izer BAL, Chroom 27%, Aluminium 7%, Molybdeen 2% | |

Skriuw jo berjocht hjir en stjoer it nei ús

Produktkategoryen

-

Telefoan

-

E-post

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top